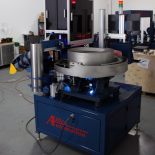

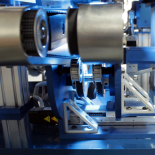

Attica Automation AV-B100 Fastener Inspection Machine was originally designed as a bolt and screw sorting machine, but it has grown into something spectacular. Built on a solid steel base, this inspection machine has been tailored to fit multiple products ranging from bolts, screws, washers, nuts, and rivets to hose fittings, airbag parts, and gaskets. Designed to fit your sorting and inspection needs, our AV-B100-G3 fastener inspection machine will still allow you to customize each and every inspection setup to fit new applications and products down the road.

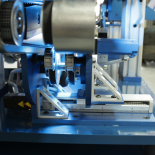

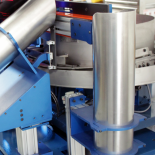

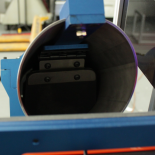

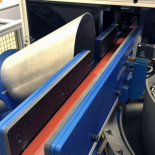

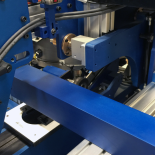

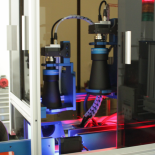

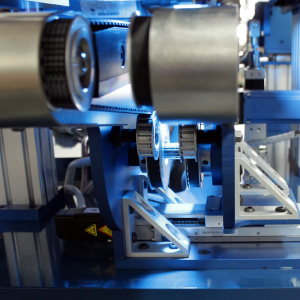

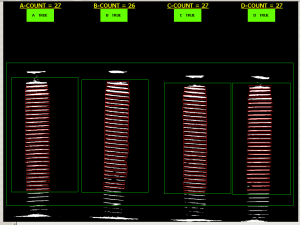

The AV-B100 Fastener Inspection Machine is a high speed inspection machine that incorporates multiple inspection methods while focusing on presenting the part to the inspection steps via a conveyor system. The subsystem that sets this inspection machine apart from the competition is the Attica Drive™ Magnetic Belt System. This system carries the product with a split belt conveyor system for head inspection and then transfers the product to a magnetic belt conveyor system for side profiling and bottom inspection. During this process, multiple inspection methods can be used to verify your part including:

The AV-B100 Fastener Inspection Machine is a high speed inspection machine that incorporates multiple inspection methods while focusing on presenting the part to the inspection steps via a conveyor system. The subsystem that sets this inspection machine apart from the competition is the Attica Drive™ Magnetic Belt System. This system carries the product with a split belt conveyor system for head inspection and then transfers the product to a magnetic belt conveyor system for side profiling and bottom inspection. During this process, multiple inspection methods can be used to verify your part including:

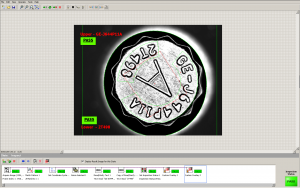

- Vision

- Image Splitting

- Eddy Current

- Lasers

- Physical Gauging

PART SPECIFICATIONS:

PART SPECIFICATIONS:

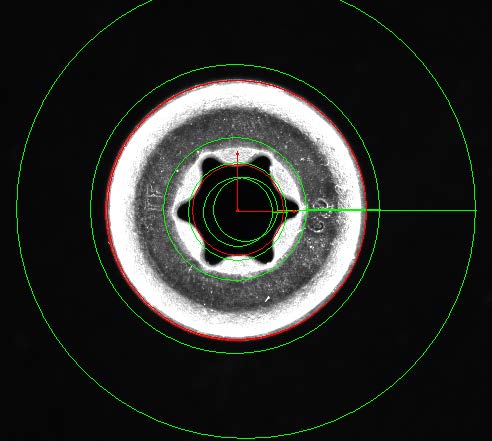

Washer

Washer All Dimensional Characteristics

All Dimensional Characteristics