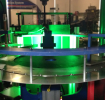

Attica Automation’s AV-D100 Inspection Machine is our highly customizable inspection and sorting machine that allows you to run the highest variety of parts on one system. Not only does this inspection machine have the ability to run as a turnkey system, but it also allows you to customize the inspection and sorting processes. Built on a solid steel frame, this inspection system has stood the test of time in the manufacturing environment while keeping its precision and accuracy.

While this machine is very similar to the AV-D100-F flat dial inspection system, the slotted dial has many different components and mechanics internally. Based on the same footprint and materials, this system also has the option for a continuous dial and indexing dial. The main difference in this system is the parts need to be able to be hung by their head. This allows this system to run a wide variety of parts, but it requires the parts to be able to hang. During this process, multiple inspection methods can also be used to verify your part including:

While this machine is very similar to the AV-D100-F flat dial inspection system, the slotted dial has many different components and mechanics internally. Based on the same footprint and materials, this system also has the option for a continuous dial and indexing dial. The main difference in this system is the parts need to be able to be hung by their head. This allows this system to run a wide variety of parts, but it requires the parts to be able to hang. During this process, multiple inspection methods can also be used to verify your part including:

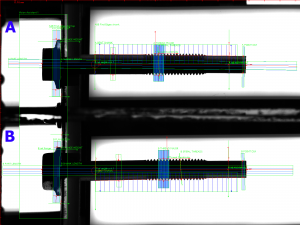

- Vision

- Image Splitting

- Eddy Current

- Lasers

- Physical Gauging

Torx® Recess Overfill

Torx® Recess Overfill